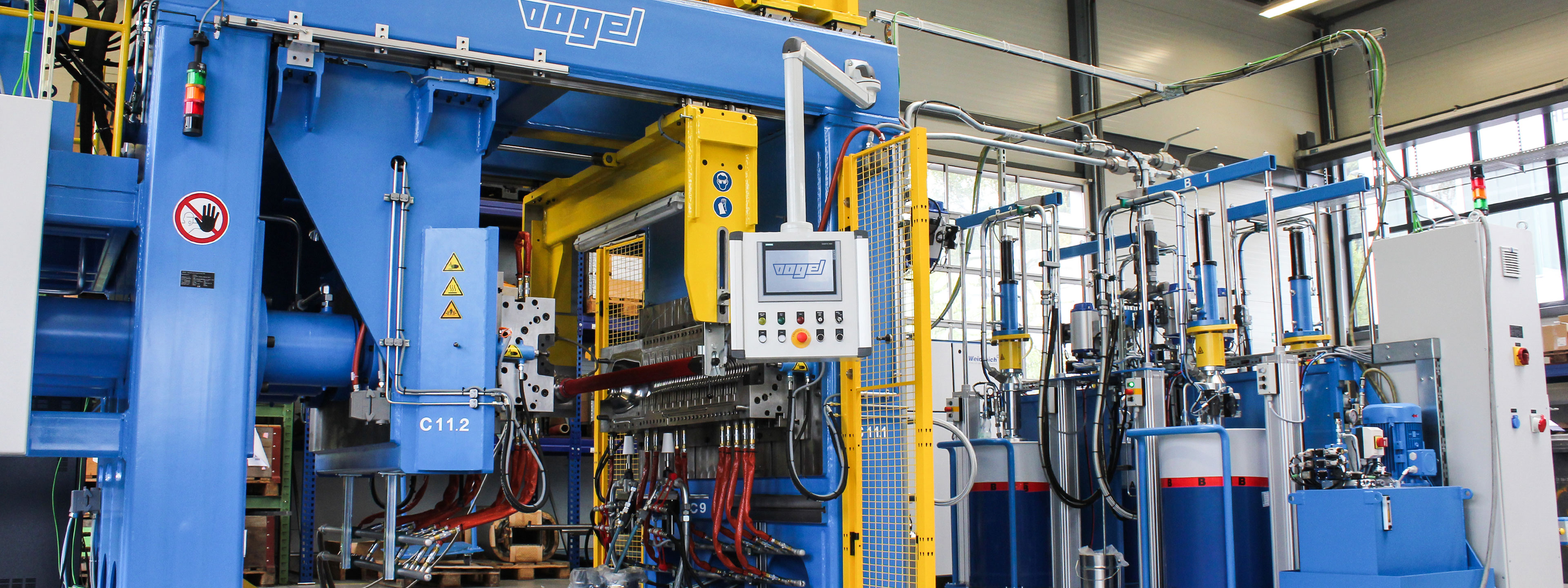

VOGEL has specialized in clamping units, moulds, mixing and dosing systems as well as customized equipment for the manufacturing of insulation parts made of epoxy resin and liquid silicone rubber (LSR) for the electrical and automotive industry. Since the APG process was invented in the early 1970s, VOGEL has been demonstrating technical capability with view to the respective equipment, e.g. the first equipment for the automatic shielding of composite insulators with liquid silicone rubber (LSR).

Nowadays, machinery and systems by Vogel moulds & machines AG are found at the highest technical level. Almost all large manufacturers of medium and high voltage equipment worldwide are among the range of customers.

- Search

-

Products

- Products

-

Technologies

- Technologies

-

Epoxy applications

- Epoxy applications

-

Clamping machines

- Clamping machines

- Albatross

- Moulds

-

Silicone applications

- Silicone applications

- Clamping machines

- Moulds

- Mixing and Dosing Systems

- Composites Applications

- Special Equipment and Solutions for Automation

- Service

-

Company

- Company

-

About VOGEL

- About VOGEL

- Management

- Member of the HEDRICH Group

- QUALITY

- VOGEL International

- News