Moulds for silicone applications

For more than 30 years, VOGEL has been famous for the moulds delivered to various clients around the world. VOGEL is capable of manufacturing all types of moulds needed in the electrical industry to produce the different types of insulators for electrical apparatuses, including the cable accessory industry. The VOGEL design team just needs a drawing of the insulators as input.

With its 3-D CAD system, the engineering department of VOGEL will then design the specific mould system.

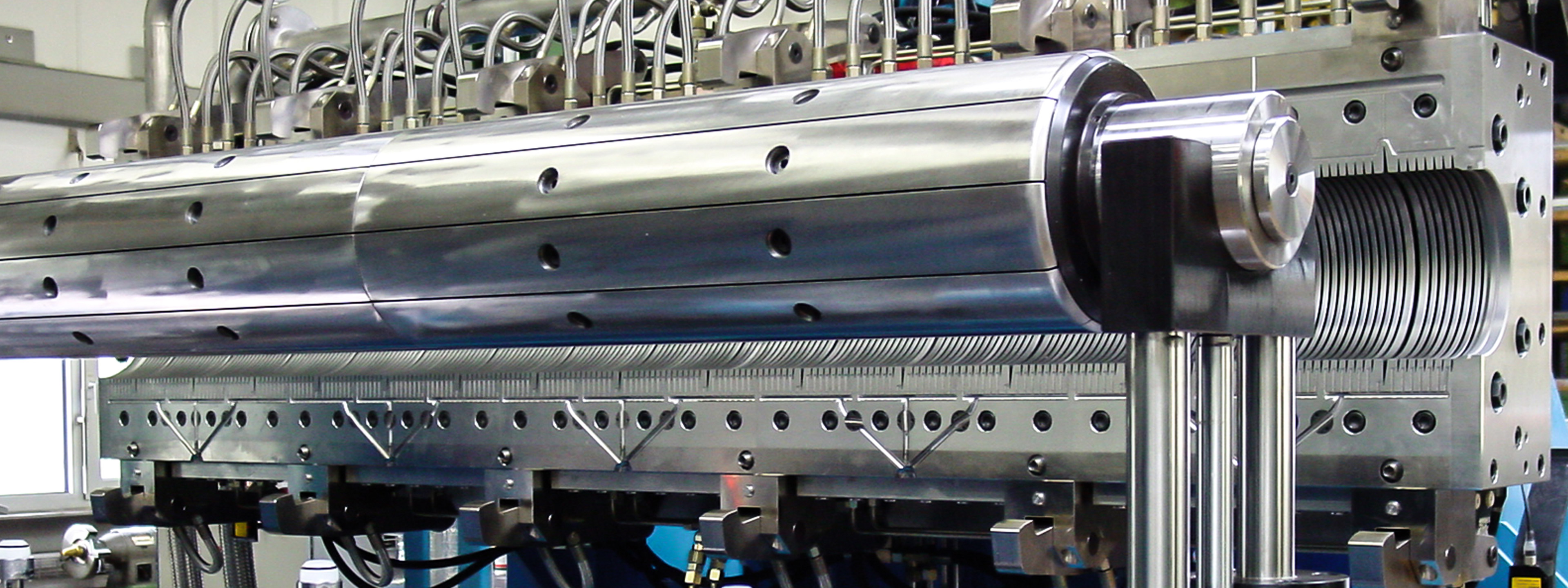

The moulds are specially designed for the client’s requirements. The heating system (electrical or water) as well as special handling systems are designed to the needs of the LSR silicone used. At this stage the required process cycle time is the most important factor to be taken into account.

Nevertheless, VOGEL has the capacity to meet any special requirements of the electrical apparatuses clients may need.

Short cycle times in moulding systems

The heating and cooling system is always customized for different applications.

For long-rod insulators an electrical heating system is often used. To heat and cool the moulds for hollow core insulators, a sophisticated system with large installed capacities is needed.

VOGEL has its special system of water distribution for heating and cooling. This assures short cycle times during the production process. For the system to be independent from the local fresh water supply, closed water systems are also available. This minimizes the need of process water.

Technical data and equipment

Technical data and equipment

Data sheet Moulds