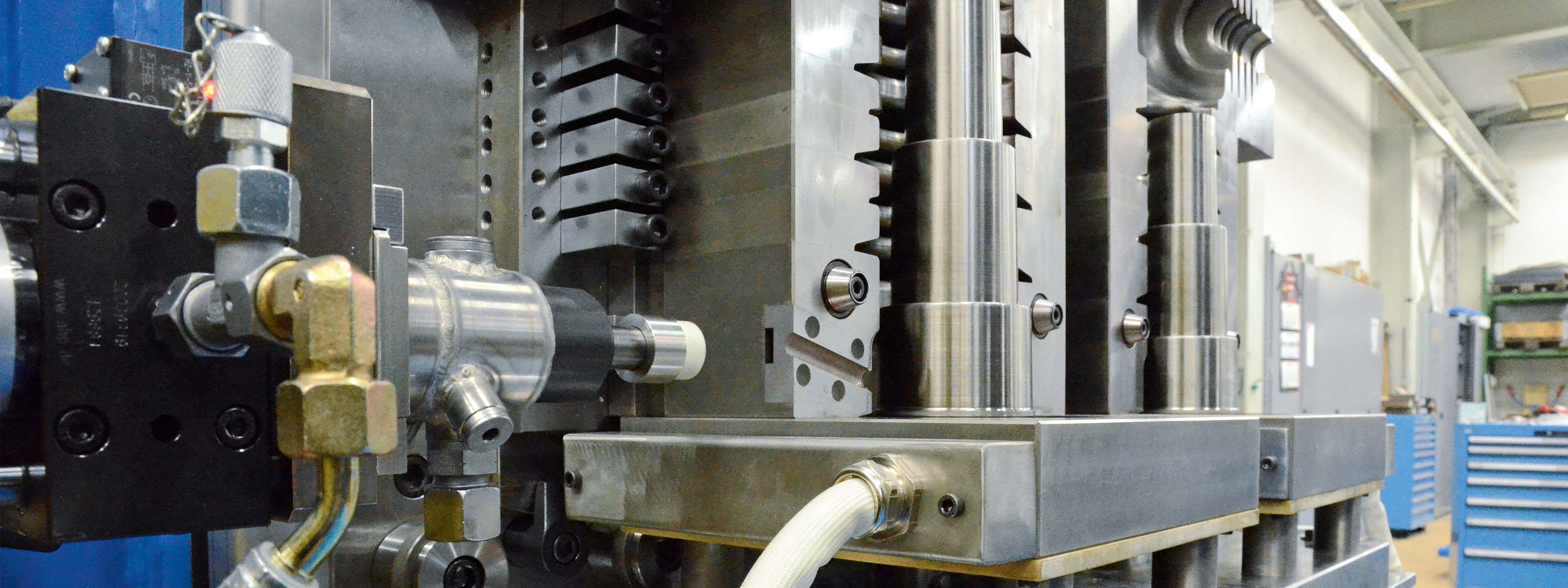

Moulds for the APG-Process

VOGEL’s mould design takes into account the typical characteristics of cast resin in order to avoid errors in casting, shrink holes and cracks. The surface quality and treatment, resp. hardening, the proper selection of the material are the basics that give the solid ground for the success of a perfect final product. Design and arrangement of the gates, vents, core pullers and insert holders complete the knowhow that VOGEL offers to customers.

Most of the moulds are in modular design to simplify maintenance or modifications of the mould. The mould can be supplied with integrated heating systems. Or it can be designed to be attached to heating plates which are mounted on the clamping units. Fully automatic demoulding and ejector-systems are built into our moulds on request. Many designs take double- or triple (up to 8 cavities) cavity tools into account in order to increase the capacity during production. Finally the special surface finish guarantees easy demoulding and an extremely long servicelife of the mould.

Besides, the moulds for the APG-process, VOGEL also provides moulds for casting of distribution transformers, vacuum casting of instrument transformers and all other types of moulds that are used in a vacuum casting process.