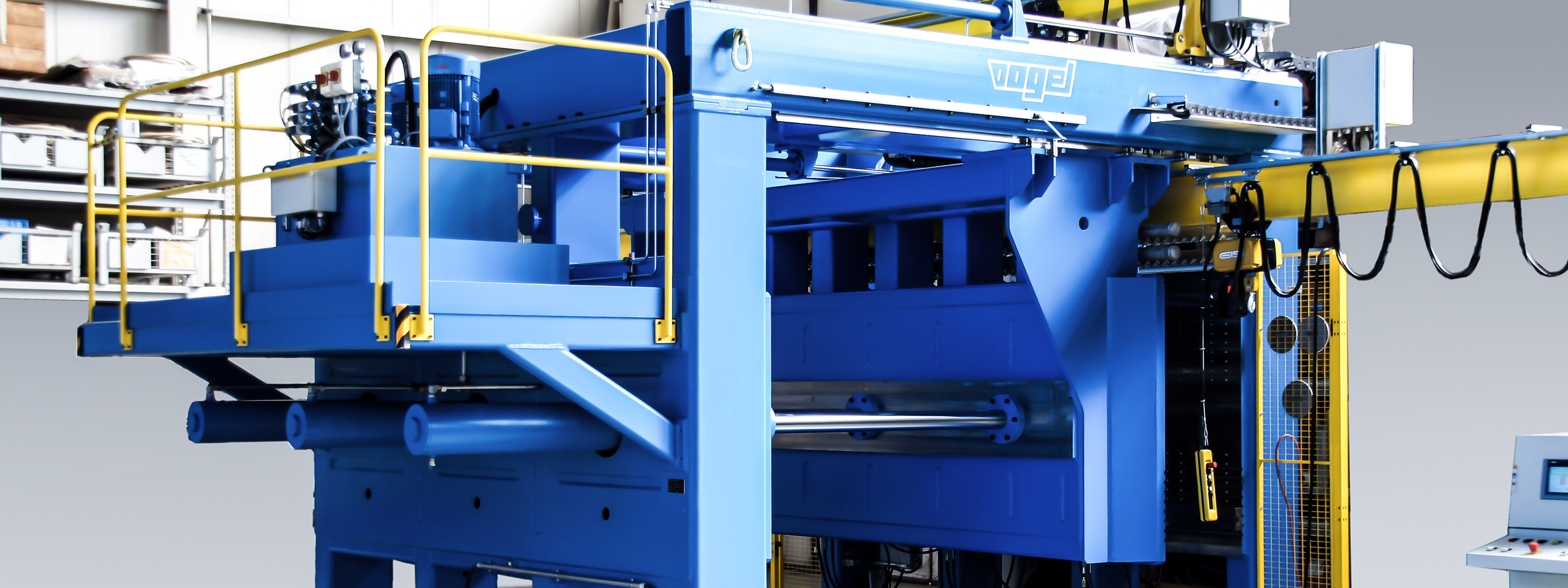

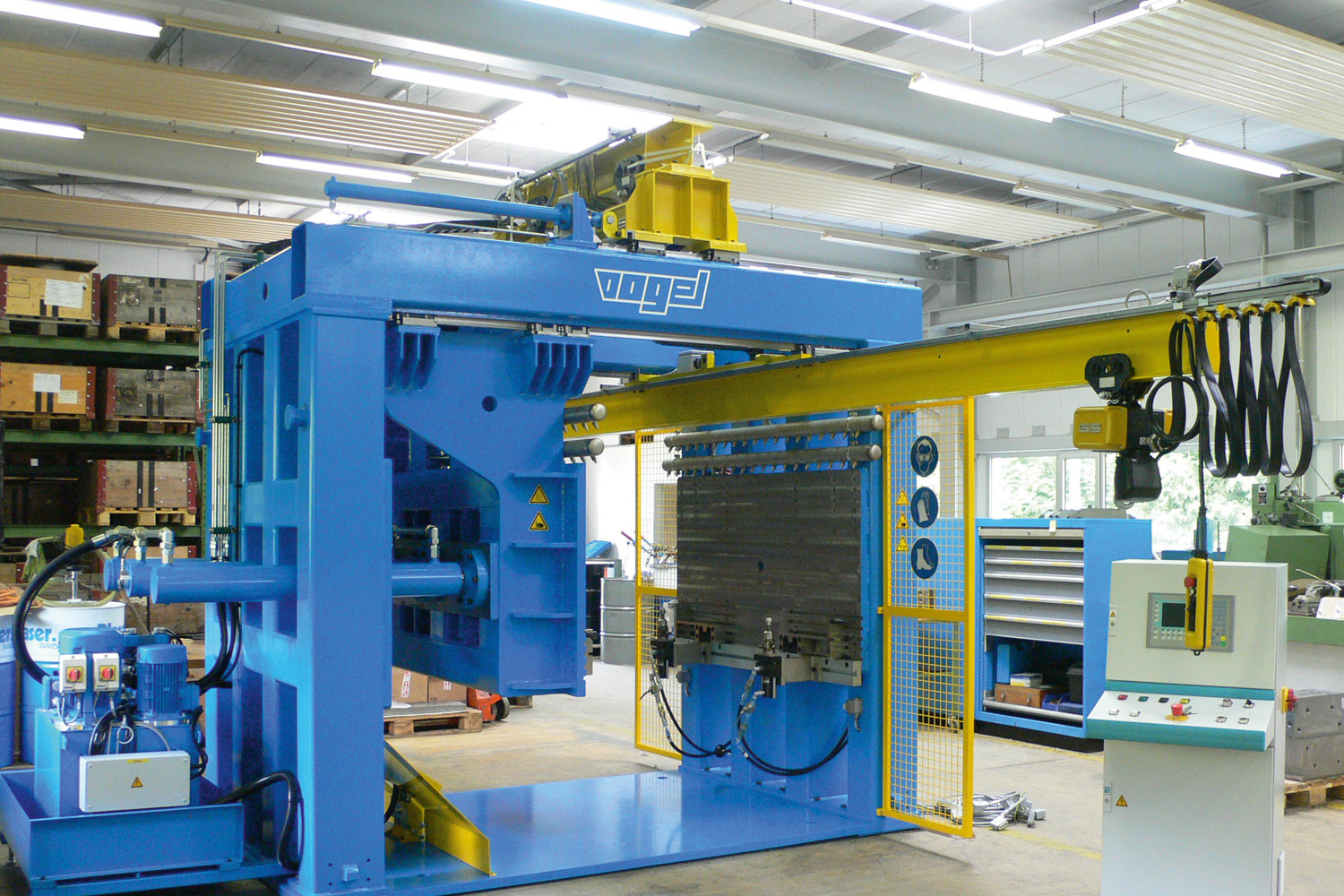

For the manufacturing process of silicone components for the electrical industry it is essential to have a clamping machine at hand that fulfils all necessary requirements during the manufacturing process. The frame construction of VOGEL clamping machines is of highest stability and precision. The wide opening extent, the flat bottom design without longitudinal bars ensure the fulfilment of the clients’ needs for a productive manufacturing process.

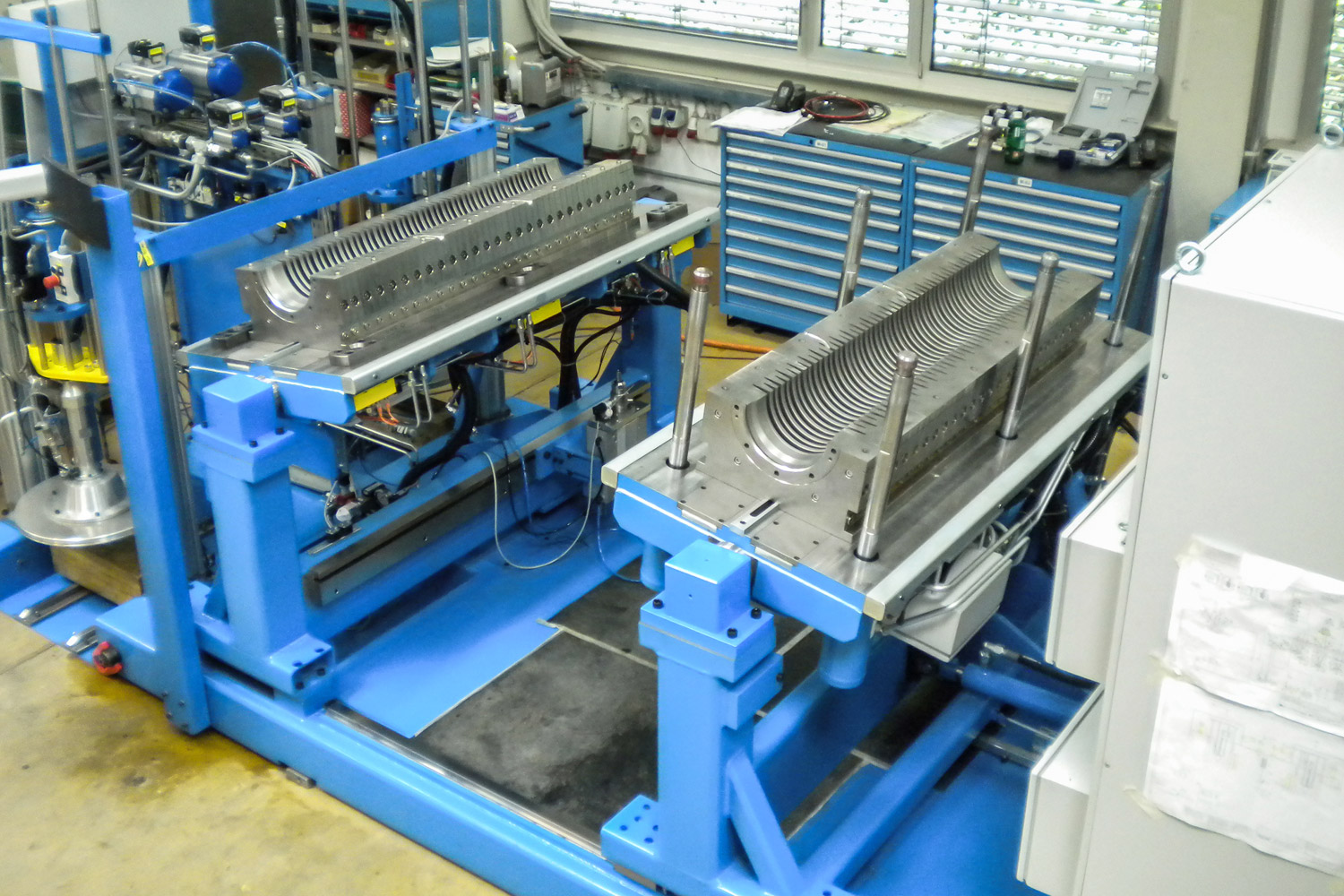

Electrical heating plates and injection nozzles combined with a self-closing mechanism may be included in the system if required. For clients with frequent mould changing requirement a fast clamping system can be added. Different types of clamping machines are in the product range of VOGEL. Every different type is specifically designed for the manufactured silicone part. The smallest clamping machines are used for the production of surge arresters or other directly-moulded electrical apparatuses. Very often a special vacuum chamber is added.

The next size of clamping machines is used for the manufacturing of long-rod insulators. These clamping machines require long backing plates. For easy and fast operation cycle time of the silicone process, a special demounting device is added to the system.

Hollow core insulators are the largest insulators made of silicone. These insulators are used for electrical apparatuses up to a maximum voltage of 800 / 1000 kV. The requirements for theses clamping machines concerning size and pressure are outstanding. This type of machine is always designed according to individual requirements of the silicone product and the silicone process used. During the past ten years, VOGEL has delivered the largest machines used for the LSR silicone process world-wide.

- Search

-

Products

- Products

-

Technologies

- Technologies

-

Epoxy applications

- Epoxy applications

-

Clamping machines

- Clamping machines

- Albatross

- Moulds

-

Silicone applications

- Silicone applications

- Clamping machines

- Moulds

- Mixing and Dosing Systems

- Composites Applications

- Special Equipment and Solutions for Automation

- Service

-

Company

- Company

-

About VOGEL

- About VOGEL

- Management

- Member of the HEDRICH Group

- QUALITY

- VOGEL International

- News