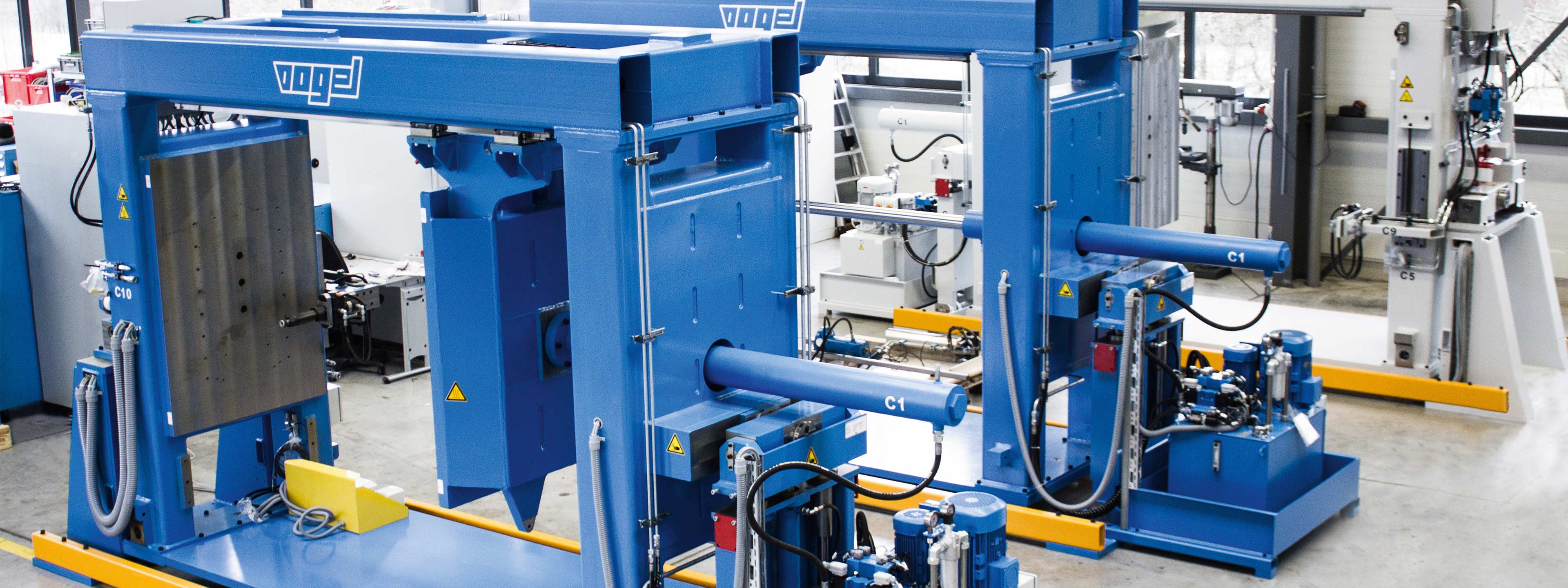

Our clamping machines for EPOXY/ PUR comprise systems for small production ranges up to the largest system available on the market. All machines have been designed with a wide opening of the mould plates and an easy “walk-in” design. The machines are fully accessible from both sides. For all types and sizes, heating plates are available. Selfclosing nozzles, various kinds of PLC and TFT touch-screen controls complete the functional capabilities of our machines. Clamping forces ranging from 180 up to 1600 kN have been built.

The clamping mechanism can be build according to Vogel’s standard type by pressing the mould or according to the method of pulling the mould together with hydraulic cylinders. These types are most advanced and keep the focus on a design of precisely closing and opening the mould including all pullers. The machine can be built as a single operating machine or as a dual-design (DUO) machine where two moulds can be placed on one machine. This increases the clamping machine capacity by up to 30%. Our machines are divided into 5 different categories that practically cover all the needs of our customers for a highly efficient production.

- Search

-

Products

- Products

-

Technologies

- Technologies

-

Epoxy applications

- Epoxy applications

-

Clamping machines

- Clamping machines

- Albatross

- Moulds

-

Silicone applications

- Silicone applications

- Clamping machines

- Moulds

- Mixing and Dosing Systems

- Composites Applications

- Special Equipment and Solutions for Automation

- Service

-

Company

- Company

-

About VOGEL

- About VOGEL

- Management

- Member of the HEDRICH Group

- QUALITY

- VOGEL International

- News