Ultra fast compound heater

In the middle of the 1990s a new concept was born for the processing of EPOXY-Resins. Up to that time, Epoxy-resin was typically injected from a pressure-pot with a temperature of approx. 30 – 40°C into the mould (not valid for 2-component dosing machines). This fairly low temperature leads to a relatively long cycle-time that limited the production-capacity.

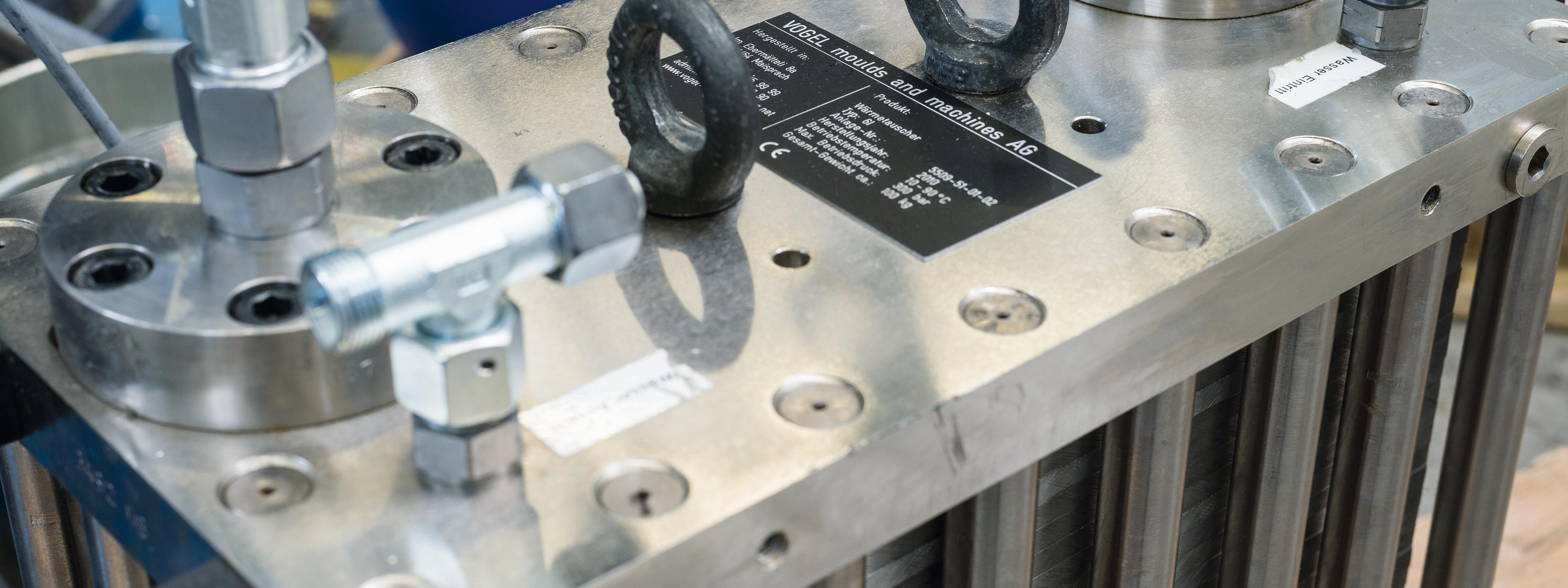

Thus the idea was born to develop a system to increase the injection temperature even before injection into the mould. With this idea, VOGEL designed and built “Ultra fast compound heater” (UFC) – units with the capacity to heat up the reactive resin “on-the-fly” prior to injection. The system is equipped with a regular pressure pot, and an inline-built heat exchanger that is capable to heat and cool the resin on the way to the mould. It is important to mention the cooling-capability to make sure that the temperature in the piping to the mould stays at a low temperature after complete injection, thus avoiding any curing of the reactive resin ahead of the mould.

The equipment comes as a completely independent unit that comprises heating/cooling capabilities besides the necessary logic and valves, including a separate PLC to run down the process automatically.