Save 30 %. With AVT!

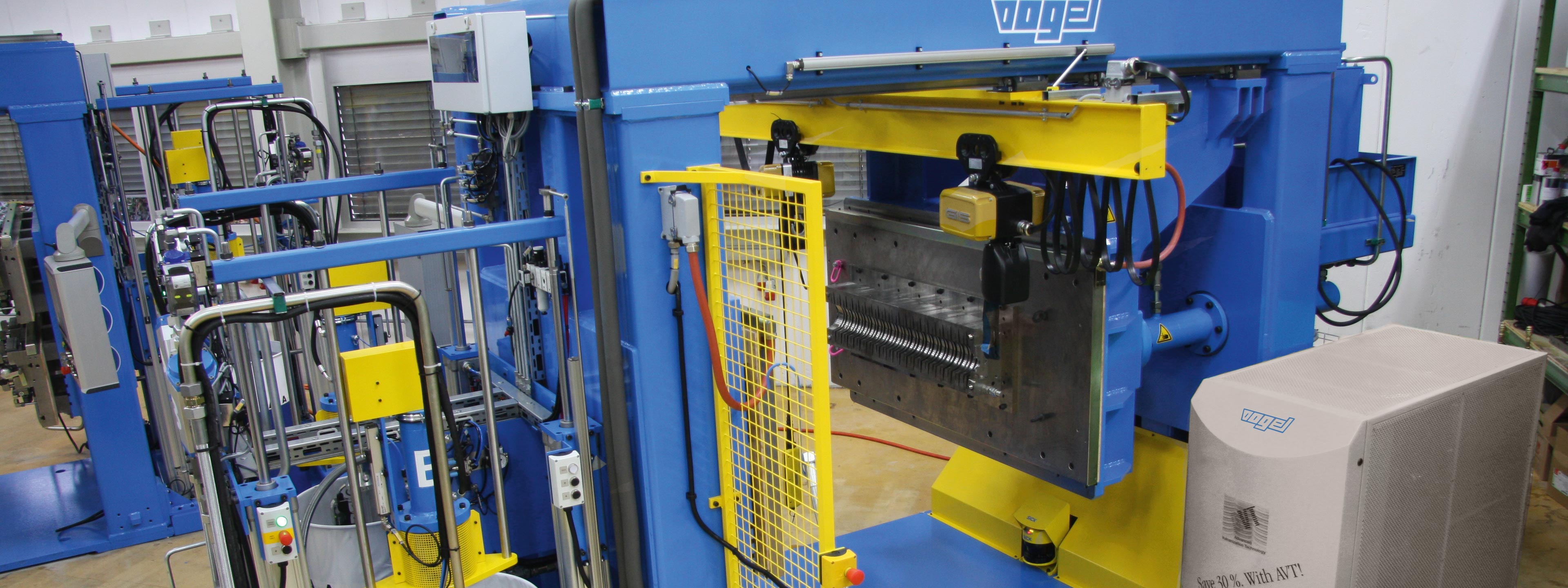

Our customers’ time is precious. Being aware of this, VOGEL engineers have developed a technology to shorten the silicone processing cycle. The benefit: improved productivity.

The “Advanced Vulcanization Technology” (AVT) uses a patented method:

Increase of inlet temperature of the processed LSR silicone, resulting in a cycle time reduced by up to 30%.

This invention is a great result of our strategy:

creating innovative and beneficial solutions for our customers.

Details:

The AVT is based on a patent of Hedrich’s for epoxy technology. This method has been adapted by VOGEL for the use of silicone processes to manufacture cable joints, hollow core insulators as well as long rod insulators.

The most effective production processes can be achieved by using AVT for the manufacturing of specific stress cones for cable joints. The LSR silicone has to have a special behaviour to show the best results.

Together with the reduction of the cycling time by up to 30 / 40% an optimal overall process may be implemented. The systems can be used for new VOGEL silicone processing systems, but also as stand-alone systems to retrofit existing systems from many suppliers.